Form fill seal machines are often divided into the types of packs they produce:

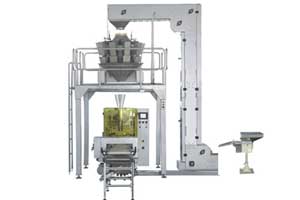

Bags and Pillow packs : flow-wrapper; lower reel flow-wrapper; vertical form fill and seal; stickpack machines; mandrel form fill seal.

Bottles/vials : blow fill seal.

Cartons : vertical carton board form fill seal.

Pots trays and blisters : cold form fill seal; thermoform fill seal; blister form fill seal.

Sachets and Envelopes : edge seal machine; horizontal form fill seal; vertical sachet form fill seal.

Sacks and Bags : tubular sack form fill seal and vertical form fill seal.